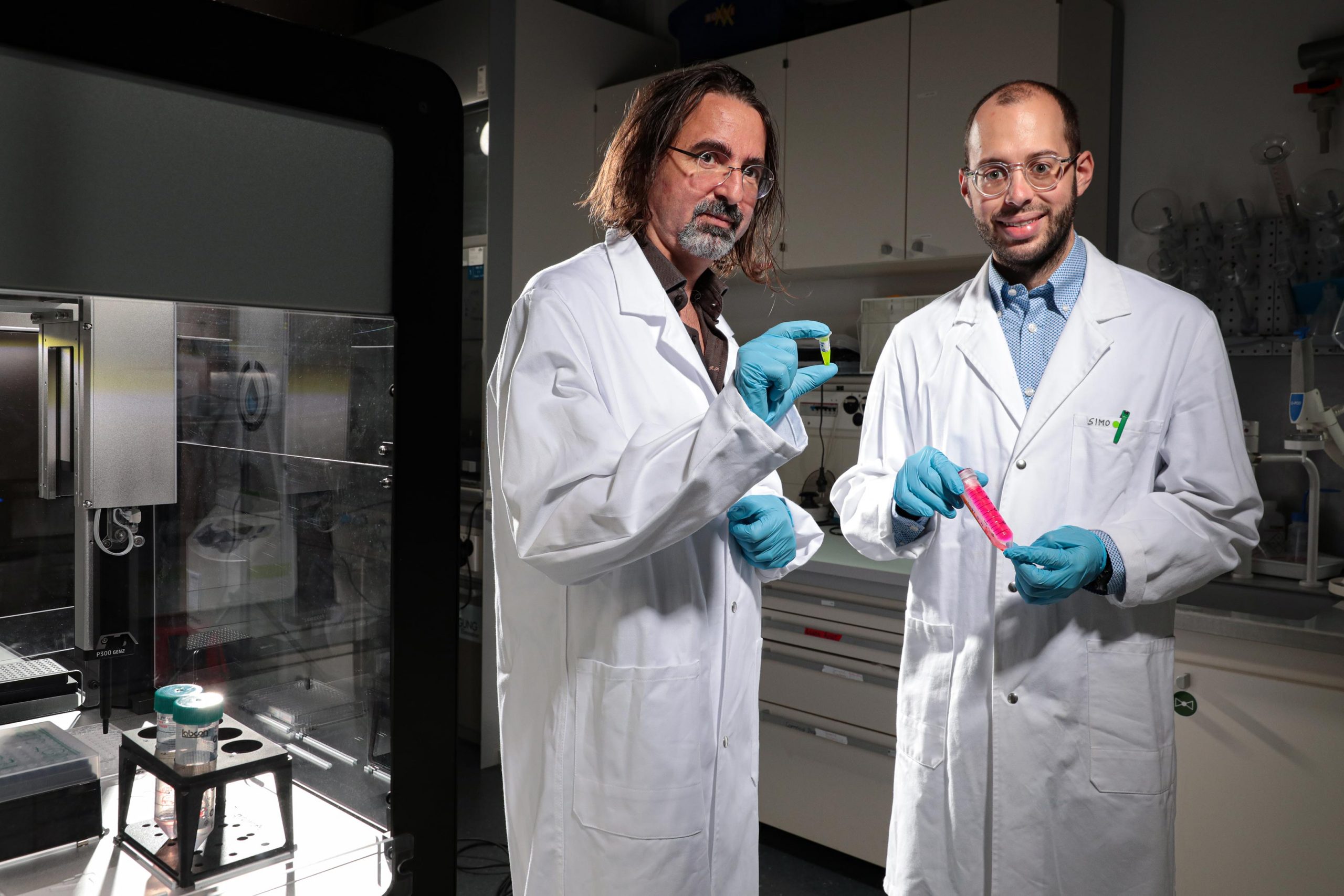

Each human being uses, on average, 30 kg of plastic per year. Given that global life expectancy currently stands at approximately 70 years, each person will discard some two metric tons of plastic in his or her lifetime. Multiply that by the number people on earth – which is growing constantly – and the total is staggering. In light of this, Francesco Stellacci, a full professor and head of the Supramolecular Nanomaterials and Interfaces Laboratory at EPFL’s School of Engineering, began thinking about whether there was a way to solve the problem of used plastics and recycle it more effectively. Stellacci established a collaboration with Prof. Sebastian J. Maerkl in the Bioengineering Institute at EPFL and they decided to co-advise a PhD student, Simone Giaveri, the team has published its conclusions, based on scientific research, in Advanced Materials.

After reviewing the existing plastic-recycling options available, the engineers decided to think up a completely new approach. “When we use biodegradable plastics, the degradation process leaves residue that must be stockpiled or buried. The more land that is allocated for this means the less land available for farming, and there are environmental consequences to take into account as bio-degradation products necessarily change the area’s ecosystem,” says Stellacci. So how can we come up with a comprehensive solution to the problem of recycling plastics? Part of the answer could very well come from nature itself.

A pearl necklace

Proteins are one of the main organic compounds of which our world is made of. Like DNA, they form part of the family of polymers; proteins are long chains of molecules, or monomers, known as amino acids. “A protein is like a string of pearls, where each pearl is an amino acid. Each pearl has a different color, and the color-sequence determines the string structure and consequently its properties. In nature, protein chains break up into the constituents amino acids and cells put such amino acids back together to form new proteins, that is they create new strings of pearls with a different color sequence,” Giaveri says.

In the lab, Giaveri initially attempted to replicate this natural cycle, outside living organisms. “We selected proteins and divided them up into amino acids. We then put the amino acids into a cell-free biological system, that assembled the amino acids back into new proteins with entirely different structures and applications,” he explains. For instance, Giaveri and Stellacci successfully transformed silk into a protein used in biomedical technology. “Importantly, when you break down and assemble proteins in this way, the quality of the proteins produced is exactly the same as that of a newly synthesized protein. Indeed, you are building something new,” Stellacci says.

Plastic is a polymer, too

So what’s the connection between protein assembly and plastic recycling? Because both compounds are polymers, the mechanisms naturally occurring in proteins could be applied to plastics as well. While this analogy may sound promising, Stellacci warns that developing such methods won’t happen overnight. “It will require a radically different mindset. Polymers are strings of pearls, but synthetic polymers are made mostly of pearls all of the same colour and when the colour is different the sequence of colour rarely matters. Furthermore, we have no efficient way to assemble synthetic polymers from different colour pearls in a way that controls their sequence.” He would also point out, however, that this new approach to plastic recycling appears to be the only one that truly adheres to the postulate of a circular economy. “In the future, sustainability will entail pushing upcycling to the extreme, throwing a lot of different object together and recycling the mixture to produce every day a different new material. Nature already does this,” he concludes.

Reference: “Nature-inspired Circular-economy Recycling (NaCRe) for Proteins: Proof of Concept” 23 September 2021, Advanced Materials.

DOI: 10.1002/adma.202104581