People have always been looking for a new energy source to replace the ones we already have, and it hasn’t been easy finding one. Fortunately, This California company, SGH2 has a hydrogen facility in the works, and has promised to transform thousands of tons of garbage into energy every year, and no other plant has been able to achieve that. According to a report by New Atlas, the hydrogen produced by SGH2 will be the “cleanest of all on the market”, and be “the cheapest,” while “pulling tens of thousands of garbage from landfills”.

Green Hydrogen

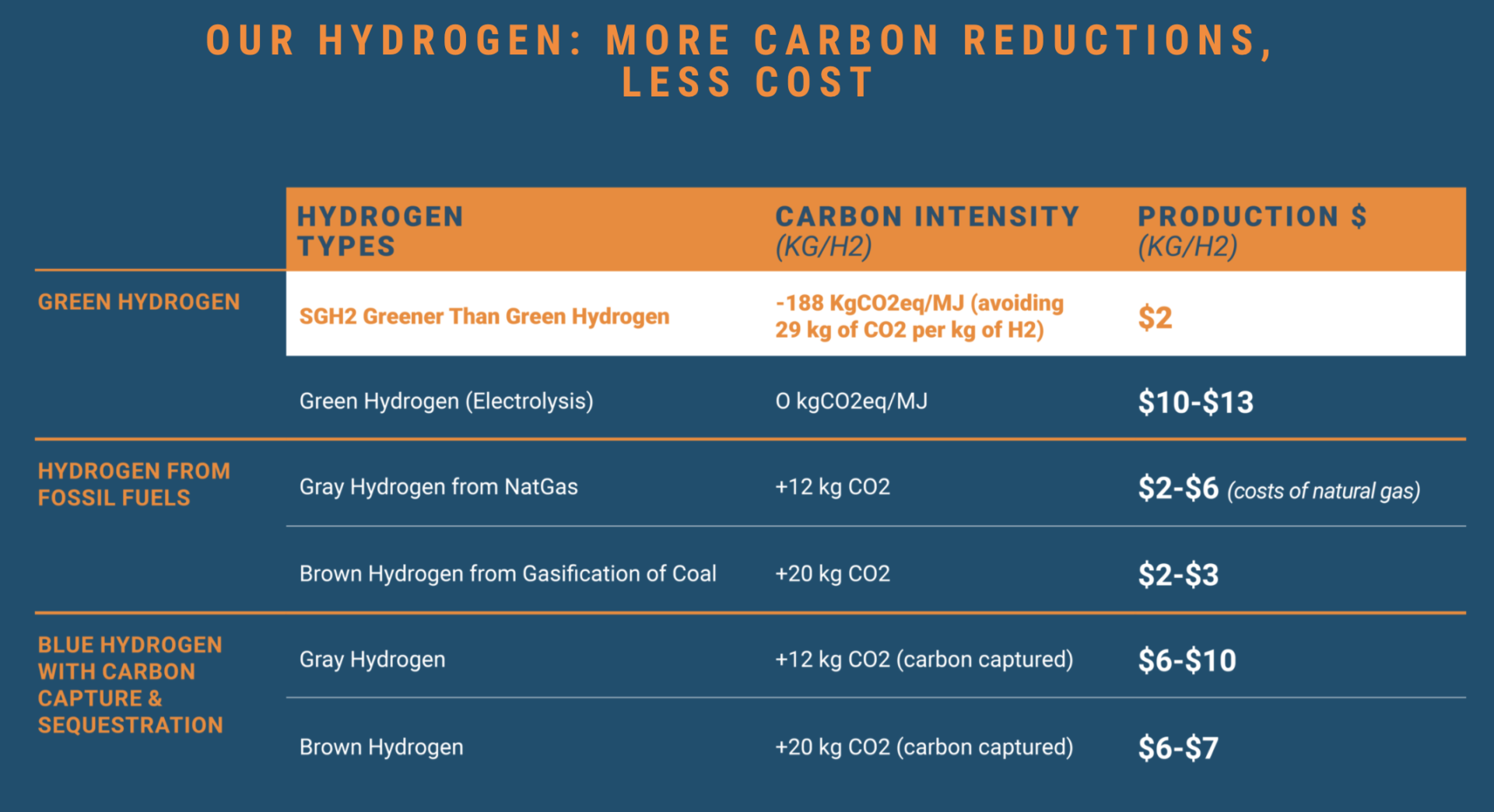

Green hydrogen is now considered by all major countries even the G20, as the leading energy carrier as a replacement for oil for the transport industry, natural gas for the heating and power industry, coal for heavy industries like cement and steel mills, and as a valuable alternative to wind and solar power. The only problem faced today is that the hydrogen is created using an expensive process, and costs around $10 per kilo of hydrogen.

“What is exciting about our technology, and the Lancaster project, is that we can produce green hydrogen four to five times cheaper than other green hydrogen, and is cost-competitive with the cheapest hydrogen made from fossil fuels,” Dr. Robert Do, SGH2 Energy president and CEO, told Digital Trends. “We have solved the biggest barrier to decarbonizing these hard to abate sectors: Cost.”

Dr. Do continued: “What is even more exciting is that we can also help fix our broken recycling industry by using massive amounts of recycled materials, which no longer have a market because China has banned their import, to produce a zero-carbon fuel — and thereby creating a sustainable circular economy.”

City of Lancaster’s SGH2 plant

According to a recent Memorandum of Understanding, the City of Lancaster is said to be hosting and co-owning the green hydrogen plant. The SGH2 Lancaster plant will be able to produce up to 11,000 kilograms of green hydrogen per day, and 3.8 million kilograms per year – nearly three times more than any other green hydrogen facility, built or under construction, anywhere in the world. The facility will process 42,000 tons of recycled waste annually. The City of Lancaster will supply guaranteed feedstock of recyclables, and will save between $50 to $75 per ton in land-filling and landfill space costs. California’s largest owners and operators of hydrogen refuelling stations (HRS) are in negotiation to purchase the plant’s output to supply current and future HRS to be built in the state over the next ten years.

As the world, and our city, cope with the coronavirus crisis, we are looking for ways to ensure a better future. We know a circular economy with renewable energy is the path, and we have positioned ourselves to be the alternative energy capital of the world. That’s why our partnership with SGH2 is so important,” said Lancaster Mayor R. Rex Parris. “This is game-changing technology. It not only solves our air quality and climate challenges by producing pollution-free hydrogen. It also solves our plastics and waste problems by turning them into green hydrogen, and does it cleaner and at costs far lower than any other green hydrogen producer.”

The plant is expected to be built on five acres in an industrial area of Lancaster. The facility will employ about 35 workers once operational, and is expected to provide more than 600 jobs during construction. The plant is estimated to take 18 months to be fully constructed. SGH2 said it expects to break ground in early 2021, with start-up and commissioning in late 2022, and full operations scheduled in early 2023. Its output will then be sold to hydrogen refuelling stations for light and heavy-duty fuel cell vehicles in California.

How it works

Developed by NASA scientist Dr. Salvador Camacho and SGH2 CEO Dr. Robert T. Do, a biophysicist and physician, SGH2’s proprietary technology gasifies any kind of waste – from plastic to paper and from tires to textiles – to make hydrogen. The technology has been vetted and validated, technically and financially, by leading global institutions including the US Export-Import Bank, Barclays and Deutsche Bank, and Shell New Energies’ gasification experts.

“The world needs some good news right now, and we have it. Affordable, mass-produced, reliable green hydrogen is the missing link needed to decarbonize the world,” said Dr. Do. “We provide that link. We are the only company in the world delivering green hydrogen that is cost competitive with the cheapest, dirtiest hydrogen made from coal and gas, and much less expensive than other green hydrogen. Our technology can scale quickly and produce fuel 24/7, year-round.”

The Lancaster plant will instead produce hydrogen by gasifying waste material using plasma torches, an “industrial tool that can raise the heat to very high levels,” Dr. Do explained.

Similar ongoing projects in other countries

SGH2 is in talks to launch similar projects in several countries, including Australia, Brazil, China, France, Saudi Arabia, Ukraine, Greece, Japan, South Korea, Poland, Turkey, Russia, and Malaysia. The company’s stacked modular design is built to be rapidly scaled, and is not dependent on weather conditions. It also does not require as much land as solar- and wind-based projects.

Tan Sri Halim Mohammad, executive chairman of the Halim Mazmin Group and owner of one of Malaysia’s largest shipping companies, noted that “Malaysia has a tremendous supply of biomass waste, which, if not used, would be burned. Using SGH2’s technology, we can convert this biomass waste to green hydrogen economically for use in land transport and shipping, which will help reduce dependency on oil and gas.”

BNEF’s analysis has said that costs for green hydrogen are forecast to fall to $2 per kilogram by 2030 in Western Europe and India. SGH2 said it already would be able to produce green hydrogen at that cost.