Solid-state drives may be the go-to for phones and most PCs and laptops, but the humble mechanical hard drive still has a place in the computing world. When you need a lot of storage for the least amount of money, they’re the way to go. And that could be the case for the foreseeable future due to a breakthrough from Cambridge University.

HDDs first appeared in the 1950s, but their use as storage devices in personal computers only took off from the mid-1980s. They have become ever smaller in size, and denser in terms of the number of stored bytes. While solid state drives are popular for mobile devices, HDDs continue to be used to store files in desktop computers, largely due to their favorable cost to produce and purchase.

HDDs contain two major components: platters and a head. Data are written on the platters using a magnetic head, which moves rapidly above them as they spin. The space between head and platter is continually decreasing to enable higher densities.

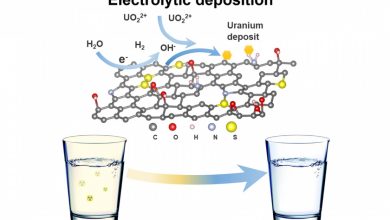

Currently, carbon-based overcoats (COCs) – layers used to protect platters from mechanical damages and corrosion – occupy a significant part of this spacing. The data density of HDDs has quadrupled since 1990, and the COC thickness has reduced from 12.5nm to around 3nm, which corresponds to one terabyte per square inch. Now, graphene has enabled researchers to multiply this by ten.

Using graphene, everyone’s favorite wonder material, they replaced the carbon-based overcoat (COC) on several hard drives. A COC protects the platter, the part of the drive that holds your data, from wear caused by its head and other factors. To build higher-density drives, manufacturers have decreased the space between the two components. Since the 1990s, the COC layer on most HDDs has slimmed down to 3nm, leading to a current storage density of about 1TB per square inch.

Graphene enables two-fold reduction in friction and provides better corrosion and wear than state-of-the-art solutions. In fact, one single graphene layer reduces corrosion by 2.5 times.

Cambridge scientists transferred graphene onto hard disks made of iron-platinum as the magnetic recording layer, and tested Heat-Assisted Magnetic Recording (HAMR) – a new technology that enables an increase in storage density by heating the recording layer to high temperatures. Current COCs do not perform at these high temperatures, but graphene does. Thus, graphene, coupled with HAMR, can outperform current HDDs, providing an unprecedented data density, higher than 10 terabytes per square inch.

“Demonstrating that graphene can serve as protective coating for conventional hard disk drives and that it is able to withstand HAMR conditions is a very important result. This will further push the development of novel high areal density hard disk drives,” said Dr Anna Ott from the Cambridge Graphene Centre, one of the co-authors of this study.

A jump in HDDs’ data density by a factor of ten and a significant reduction in wear rate are critical to achieving more sustainable and durable magnetic data recording. Graphene based technological developments are progressing along the right track towards a more sustainable world.

Professor Andrea C. Ferrari, Director of the Cambridge Graphene Centre, added: “This work showcases the excellent mechanical, corrosion and wear resistance properties of graphene for ultra-high storage density magnetic media. Considering that in 2020, around 1 billion terabytes of fresh HDD storage was produced, these results indicate a route for mass application of graphene in cutting-edge technologies.”

The study, published in Nature Communications, was carried out in collaboration with teams at the University of Exeter, India, Switzerland, Singapore, and the US.

The research team pushed beyond that limit by taking advantage of graphene’s heat resistance. That aspect of the material allowed the team to leverage a separate emerging technology called Heat-Assisted Magnetic Recording (HAMR). It enables a platter to hold even more data when it’s heated. That’s not something you can do with a traditional COC.

Together, the technologies may lead to HDDs with a storage density between four and 10 terabytes per square inch. But beyond allowing for drives with significantly more capacity, graphene HDDs promise to be more resilient as well. The researchers found a single layer of the material reduced corrosion by 2.5 times. It also reduced friction and wear better than other current state-of-the-art solutions. When it comes to hard drives, reliability is just as important as storage capacity and what is likely to get cloud operators like Google interested in the technology.

But then there’s the catch that comes with every graphene-related breakthrough we’ve since the material’s discovery in 2004. It could allow us to do many things, including filter water more efficiently and selectively kill off cancer cells, but so far, most of those applications have yet to make it out of the lab and into the real world.