It is no secret that technology has helped and improved the working environment for many and no more than in the manufacturing industries, making them safer to work in, more comfortable, as well as making production itself a lot faster.

It is not only in this that the benefits have been felt. Indeed, there are ways that you can still embrace even more technology into your business and watch it improve your business from every aspect possible.

Being Able to Go Paperless

Being paperless is a big thing in the manufacturing industry, especially when the business concerned is manufacturing electrical components or fitting them to circuit boards.

ESD: Too much paperwork or any, in fact, within a certain distance of a board or component can cause electrical static discharge which can damage electrical components to the point of destruction. However, there are ways to get around the problem of requiring the information carried on paper around your site, such as drawings, instructions, procedure plans, and test results.

Tablets: Personal tablets could very well be issued to every member of your manufacturing workforce so that they still have access to the important documentation that they require to carry out their job roles and to be able to see where the job must go when they have finished their task.

Manuals: From time to time, you are going to want to update your procedures and you will probably have manuals such as the IPC manuals that get updated sporadically with a new edition. By having a paperless environment, you will find that updating or adjusting your procedures and your manuals a particularly easy and time-saving project, not to mention the saving on paper, ink or toner that is required when printing out large documents.

When it comes to providing access for your workforce to the important updated editions of manuals such as the IPC manuals, you will not have to purchase multiple books, but just have one company version available on your computer system.

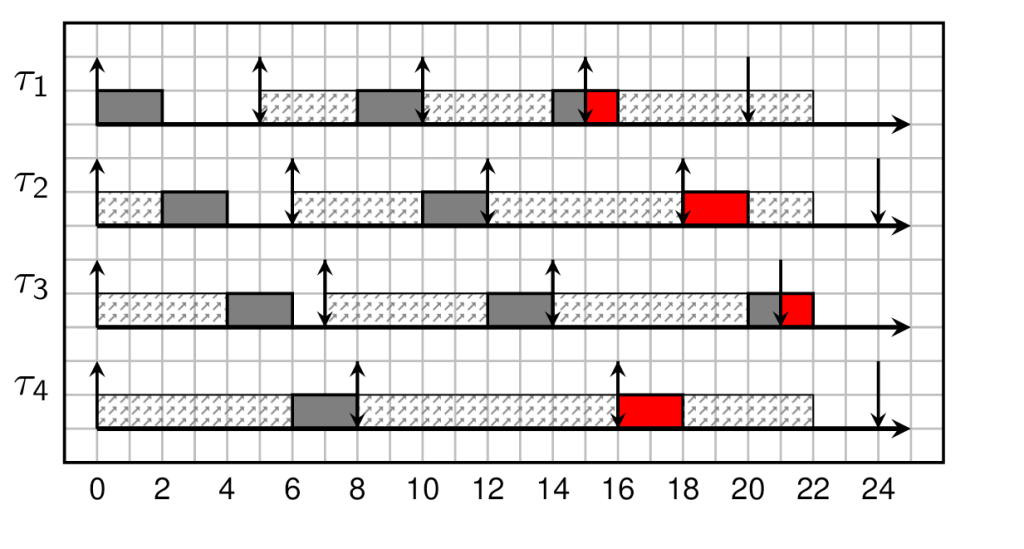

Scheduling and Deadlines

With the use of technology and scheduling software, you can now keep on track of workloads around your premises. If you give all of your manufacturing employees access to their workload schedule and teach them how to update the information on there, you will find that you will be able to keep close tabs on what is going on with every order you have in production. This will help immensely when it comes to working out deadlines, as well as proving you with a heads up should the order be put on hold due to issues or have rework that is required to be carried out.

Parts Production

You can invest in your very own mold shop or workshop area to provide your factory with your very own parts which are bespoke to your business. However, with the help of technology, there is a possibility that you would now be able to produce those parts using a 3D printer. Although there is an initial expense to this, it could save you money in the long-term if you regularly need to create new parts. Of course, there are other maintenance and training issues that can also cause negative impacts.

3D printers are an expensive luxury and if you have one on-site you likely have an operator that is especially skilled at working with it and understands how the 3D printer works as well as can program it. However, this is an expense that you can waive, by using the services of a 3d printing high-volume production business that offers your manufacturing business can reap all the benefits of using a 3D printer but without the added stress, loss of manufacturing space, or expense of buying a 3D printer.

Online Training and Certification

There are also benefits to the training and certification process of employees. Of course, there are many bonuses to having face-to-face training courses, and some areas of a business do benefit heavily from this, such as IPC training, even though the coursework and exam itself are carried out online.

There are employee training courses that are in-house, such as health and safety training and any HR training courses that can, not only be taught virtually but also be assessed and examined without supervision.

Either way, if certification is required or gained at the end of any course where the exam is carried out online, you are now able to find out the results and print your certificate at the end of the exam rather than having to wait days or even weeks for the certification to come through the mail to your door.