Booming electric vehicle sales have spurred a growing demand for lithium. But the light metal, which is essential for making power-packed rechargeable batteries, isn’t abundant. Now, researchers report a major step toward tapping a virtually limitless lithium supply: pulling it straight out of seawater.

“This represents substantial progress” for the field, says Jang Wook Choi, a chemical engineer at Seoul National University who was not involved with the work. He adds that the approach might also prove useful for reclaiming lithium from used batteries.

Lithium is prized for rechargeables because it stores more energy by weight than other battery materials. Manufacturers use more than 160,000 tons of the material every year, a number expected to grow nearly 10-fold over the next decade. But lithium supplies are limited and concentrated in a handful of countries, where the metal is either mined or extracted from briny water.

Lithium’s scarcity has raised concerns that future shortages could cause battery prices to skyrocket and stymie the growth of electric vehicles and other lithium-dependent technologies such as Tesla Powerwalls, stationary batteries often used to store rooftop solar power.

Seawater could come to the rescue. The world’s oceans contain an estimated 180 billion tons of lithium. But it’s dilute, present at roughly 0.2 parts per million. Researchers have devised numerous filters and membranes to try to selectively extract lithium from seawater. But those efforts rely on evaporating away much of the water to concentrate the lithium, which requires extensive land use and time. To date such efforts have not proved economical.

Choi and other researchers have also tried to use lithium-ion battery electrodes to pull lithium directly from seawater and brines without the need for first evaporating the water. Those electrodes consist of sandwichlike layered materials designed to trap and hold lithium ions as a battery charges. In seawater, a negative electrical voltage applied to a lithium-grabbing electrode pulls lithium ions into the electrode. But it also pulls in sodium, a chemically similar element that is about 100,000 times more abundant in seawater than lithium. If the two elements push their way into the electrode at the same rate, sodium almost completely crowds out the lithium.

To get around this problem, researchers led by Yi Cui, a materials scientist at Stanford University, looked for ways to make electrode materials more selective. First, they coated an electrode with a thin layer of titanium dioxide as a barrier. Because lithium ions are smaller than sodium, it is easier for them to wriggle through and into the electrode sandwich.

The researchers also changed the way they controlled the electric voltage. Instead of applying a constant negative voltage to the electrode, as others had done, they cycled it. First, they applied a negative voltage, and then they briefly turned it off. Next, they applied a positive voltage, turned it off again, and repeated the cycle.

The change in voltage, Cui explains, causes lithium and sodium ions to move into the electrode, stop, and then start to move back out when the current reverses. However, because the electrode material has a slightly higher affinity for lithium than sodium, lithium ions are the first to move into the electrodes and the last to leave. So, repeating this cycle concentrates lithium in the electrode. After 10 such cycles, taking just minutes, Cui and colleagues ended up with a one-to-one ratio of lithium to sodium, they report this month in Joule.

“That doubles the selectivity, at least,” compared with previous attempts to use battery electrodes to harvest lithium, says Chong Liu, a materials scientist at the University of Chicago who previously was a postdoctoral scientist in Cui’s laboratory.

The advance is still not likely cheap enough to compete with mining lithium on land, Liu says. However, she says her group is attempting to increase selectivity using other types of lithium-ion battery electrodes.

Choi adds that the approach might also prove useful for recovering lithium from discarded batteries, giving the metal a second lease on life—and potentially supercharging the ascendancy of electric vehicles.

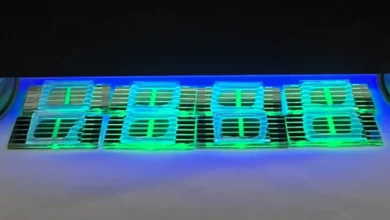

Enriching the lithium content in seawater via an electrochemical cell

The research team from KAUST developed an electrochemical cell containing a ceramic membrane composed of lithium lanthanum titanium oxide (LLTO), whose crystal structure possesses holes wide enough to allow lithium ions to move through, while also blocking the larger metal ions. “LLTO membranes have never been used to extract and concentrate lithium ions before,” said Zhen Li, a postdoc researcher who developed the cell. The cell is comprised of three compartments: First, seawater flows into the central feed chamber, and then positive lithium ions move through the LLTO membrane, and into an adjacent compartment equipped with a buffer solution, in addition to a copper cathode coated in ruthenium and platinum.

While this is happening, negative ions leave the feed chamber via a standard anion exchange membrane, and pass through a third section containing a sodium chloride solution, and a platinum-ruthenium anode. The new lithium-extracting system was tested with seawater sucked up from the Red Sea, and with a voltage of 3.25 V, the cell can generate chlorine gas at the anode, and hydrogen gas at the cathode. This directs the lithium through the LLTO membrane, where it aggregates in the side-chamber from above. The result is lithium-enriched water that is then fed back into the cell through four more cycles of processing, enriching the element’s concentration until it reaches 9,000ppm.

Five dollars of electricity is needed per kilogram

The researchers then alter the pH of the solution, creating a solid lithium phosphate that only contains traces of other metal ions. In other words, the final product is pure enough to fall within all-electric vehicle battery manufacturers’ standards to build. This process would require only five dollars of electricity to extract 2.2 lbs (1 kg) of lithium from seawater. Five dollars!

And, the value of chlorine and hydrogen produced from the cell would more than pay for the cost, leaving residual seawater to be used in desalination plants to offer freshwater. “We will continue optimizing the membrane structure and cell design to improve the process efficiency,” said Zhiping Lai, who leads KAUST. His team also aims to enter a collaboration with the glass industry, to develop the LLTO membrane at greater scales with affordable cost.

Needless to say, this is an extremely promising system. Auto manufacturers like Ford are increasingly following Tesla’s lead in pivoting to all-electric, to eventually move away from fossil fuels, which are linked to high carbon emissions and global climate. But if we run out of lithium, these plans are only stop-gaps for the transportation and auto industries. This is why, most crucial to the KAUST team’s electrochemical cell is not the ability to simply procure concentrated lithium ions, but the capability to do it at low cost, with sustainable outputs.